Silicon is the element of the electronic age. From tiny microchips to mammoth LCD television screens, the semiconducting metalloid plays a central role in the devices that define modern life.

But silicon’s uses go well beyond computing and consumer electronics. It is handy in all sorts of industrial and technological applications, including solar technology. Black silicon, a variant that absorbs 99 percent of light, makes for powerful solar panels.

Now, University of Wisconsin-Madison researchers, led by Materials Science and Engineering Professor Xudong Wang and graduate student Yanhao Yu, and their collaborators at the University of Science and Technology Beijing, Professors Yue Zhang and Zheng Zhang, are reporting a nanotechnology breakthrough that could help set the stage for a black silicon-powered revolution in clean fuel production.

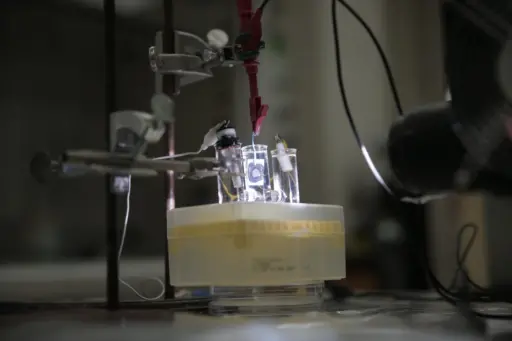

A three-electrode photochemical testing system is the centerpiece of this research. A black silicon sample (center) absorbs simulated sunlight and generates oxygen on its surface. Meanwhile, hydrogen is produced on the platinum electrode (right). Photo by Stephanie Precourt.

A three-electrode photochemical testing system is the centerpiece of this research. A black silicon sample (center) absorbs simulated sunlight and generates oxygen on its surface. Meanwhile, hydrogen is produced on the platinum electrode (right). Photo by Stephanie Precourt.

The promise—and challenge—lies in black silicon’s special nanostructure. Typical silicon has a nanostructure that’s relatively smooth. Meanwhile, black silicon’s nanostructure is very rough. This coarse texture causes incoming light to bounce back into the silicon rather than reflect out as it would with typical silicon.

The light-absorbing quality makes black silicon an attractive material for solar panels, which need to absorb as much solar energy in the form of light as possible to maximize their efficiency. The technology is well-developed, and there are other ways that black silicon’s light absorption properties could be useful.

That’s if researchers can figure out how to overcome a key obstacle posed by black silicon’s rough nanostructure.

Wang’s research is focused on this obstacle. He hopes to use black silicon as a solar-powered generator of chemical energy such as hydrogen fuel. The idea is that the power black silicon derives from its efficient solar absorption could be harnessed to split water molecules and create hydrogen fuel through a photo-electro-chemical process. This would represent an efficient, renewable and clean alternative to present methods of hydrogen fuel production.

There’s one catch: Black silicon’s surface, while advantageous in its light absorption properties, is very unstable and reactive—precisely because of its rough texture.

This reactive surface is especially problematic in the context of hydrogen fuel production because the best liquid to produce hydrogen fuel by splitting hydrogen and oxygen atoms is not actually pure water. Rather, electrolyte solutions like sodium hydroxide, which are more conductive than water, are much more efficient in the photo-electro-chemical process that converts solar energy into hydrogen fuel.

But sodium hydroxide is highly corrosive. When black silicon comes into contact with the solution—as it must to initiative the photo-electro-chemical process that creates hydrogen fuel—its reactive surface quickly corrodes and becomes useless.

To solve this problem, Wang’s team sought to give black silicon’s rough and reactive surface a protective coating. The coating needed to be thick enough to prevent the electrolyte from coming into contact with the black silicon but thin enough to allow the silicon to absorb sunlight. To accomplish this, Wang used a technique called atomic layer deposition, which exposes a surface to gaseous precursors to create a pin-hole-free and very uniform thin film. In this case, Wang deposited a 10-nanometer-thick layer of titanium dioxide onto the black silicon’s surface. The results were very promising.

Not only does the titanium dioxide provide a protective coating that prevents the corrosive electrolyte from reacting with the silicon, it’s so thin that it doesn’t affect light absorption. It also enhances the efficiency of the whole energy conversion process by reducing the black silicon’s surface defects, according to Wang.

“This development really shows the feasibility of this technology,” says Wang. “This was a fundamental study in a very active research field that I think can lead to major research opportunities.”

The next step for Wang’s team is to figure out how to maximize the lifetime of the thin protective coating. Right now, the coating does not last long enough to make the technology commercially viable. But Wang says his team has already significantly improved its lifetime since their first success in demonstrating its feasibility. If they can extend its lifetime enough, there may one day soon be an affordable supply of solar-generated hydrogen fuel, which would represent an exceptionally clean and renewable fuel supply.

The research appeared in the March 27, 2017, issue of the journal Nature Energy.

This work was funded in part by the United States Department of Energy (DOE), Office of Science, Basic Energy Sciences (BES). This work was also supported in part by the National Major Research Program of China; the Program of Introducing Talents of Discipline to Universities; National Natural Science Foundation of China; and Beijing Municipal Science & Technology Commission.