During a September 2024 makeathon at the University of Wisconsin-Madison Grainger Engineering Design Innovation Lab @ Wendt, dozens of volunteers from across the UW-Madison community created assistive mobility devices for toddlers.

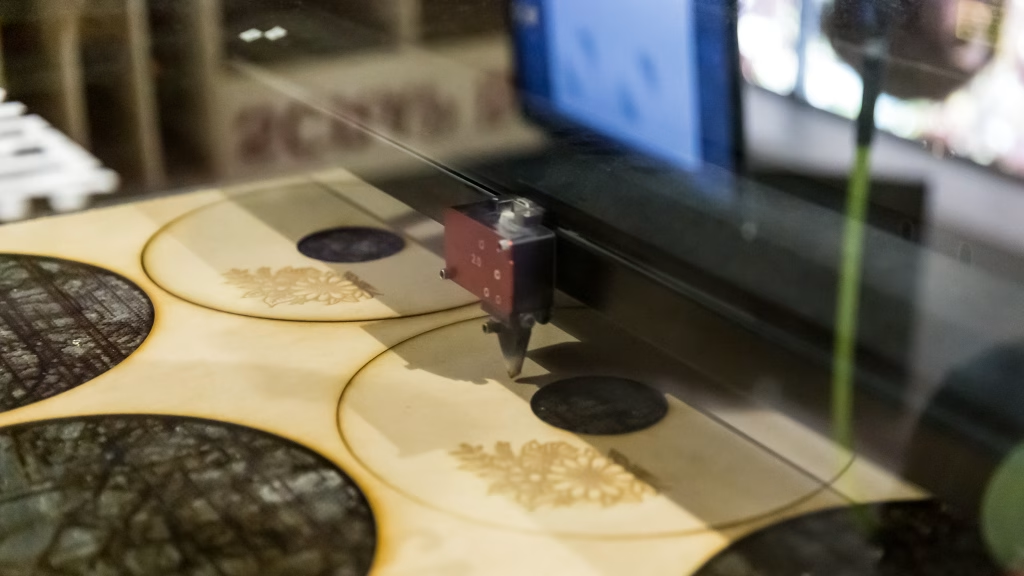

In teams, volunteers built modified toddler mobility trainers—or mobility assistance devices for children who aren’t yet big or old enough for wheelchairs. At one workstation, volunteers worked on fabric seat cushions, while others assembled frames at another. Teams at a different station used a laser etching machine to add designs to wood disks for additional flair on the wheels’ exteriors.

The volunteers also added a few improvements to the existing mobility trainer design. Peter Noonan, a mechanical engineering graduate student who helped organize the makeathon, says most of those were personalized flair for the trainers’ recipients. Volunteers made 10 mobility trainers, six of which were distributed to families. The remaining four will be used at local clinics.

“We added a tray for feeding purposes, and some other adjustments,” Noonan says. “But the main additions were cosmetic customizations. We had some information about the kids and the kinds of cartoons or music they like, so we put some of those into elements like the wheel cover designs. We designed those, and the teams are making them so the kids will have something that’s just a little bit more tailored to them specifically.”

Fazlina Desmawardi, a junior studying chemical engineering, prepares fabric that will go into the seat for a toddler mobility trainer.

Fazlina Desmawardi, a junior studying chemical engineering, prepares fabric that will go into the seat for a toddler mobility trainer.

Lab Director Lennon Rodgers says each annual makeathon has a theme—in 2023, for example, it focused on the health risks marginalized groups face from rising global temperatures—and each is coordinated with campus and external partners. Makeathons primarily draw students, but are also open to staff, faculty and alumni; about 50 people participated in the 2024 event.

Makeathons encourage collaboration across disciplines and allow volunteers to use the array of tools and equipment available in the Design and Innovation Lab, all while working toward a common goal. The Design and Innovation Lab coordinated with the Doctor of Physical Therapy program in the UW-Madison School of Medicine and Public Health to host this year’s event. Rodgers says several students, faculty and staff from the program were instrumental to organizing the event and connecting with families in need of the mobility trainers.

Madison-based national architectural firm Erdman was one supporting partner for the 2024 Makeathon, and CEO Rustin Becker joined in volunteer efforts. Becker says Erdman has a connection through Noam Platt, an architect in the firm’s New Orleans office who founded MakeGood, a nonprofit organization focused on assistive mobility devices like the toddler mobility trainers. Tikkun Olam Makers created the original design for the toddler mobility trainers.

“This has been a wonderful opportunity to work with the students, who are leveraging their skills to actually bring something together and, at the end of the day, see the impact it’s going to have for the children who get these chairs,” Becker says.

The Plexus Interdisciplinary Engineering Design program also co-sponsored the event.

Top featured image caption: Mechanical engineering senior Grace Morgan (foreground) and master of design and innovation student Quyen Tonnu piece together the seat of a toddler mobility trainer during the 2024 makeathon.

Mechanical engineering senior Lexi Manchester, master of design and innovation student Isabel Stang, and mechanical engineering senior Ethan Dretzka (from left) discuss their work while looking at a toddler mobility trainer.

Mechanical engineering senior Lexi Manchester, master of design and innovation student Isabel Stang, and mechanical engineering senior Ethan Dretzka (from left) discuss their work while looking at a toddler mobility trainer.

A laser etching machine in the Design and Innovation Lab in the process of engraving a pattern into a piece of wood. Volunteers at the 2024 makeathon used the machines to create custom wheel covers.

A laser etching machine in the Design and Innovation Lab in the process of engraving a pattern into a piece of wood. Volunteers at the 2024 makeathon used the machines to create custom wheel covers.

Eli Gudmestad, a freshman in mechanical engineering, uses a sewing machine in the Design and Innovation Lab. He worked on the team of volunteers that made seat cushions for the mobility trainers.

Eli Gudmestad, a freshman in mechanical engineering, uses a sewing machine in the Design and Innovation Lab. He worked on the team of volunteers that made seat cushions for the mobility trainers.

A toddler mobility trainer. Volunteers worked on modifications to the mobility assistance devices, which are essentially wheelchairs for very young children, during the 2024 Makeathon.

A toddler mobility trainer. Volunteers worked on modifications to the mobility assistance devices, which are essentially wheelchairs for very young children, during the 2024 Makeathon.