When Greg Nellis and Kris Dressler set out to revamp the hands-on design project for ME 201: Introduction to Mechanical Engineering, they saw an opportunity to also help prepare students for their statics course.

“Statics is a very foundational course for mechanical engineering students and is important for their progression in the major. It’s also a challenging course for many students,” says Nellis, the William A. and Irene Ouweneel-Bascom Professor in mechanical engineering.

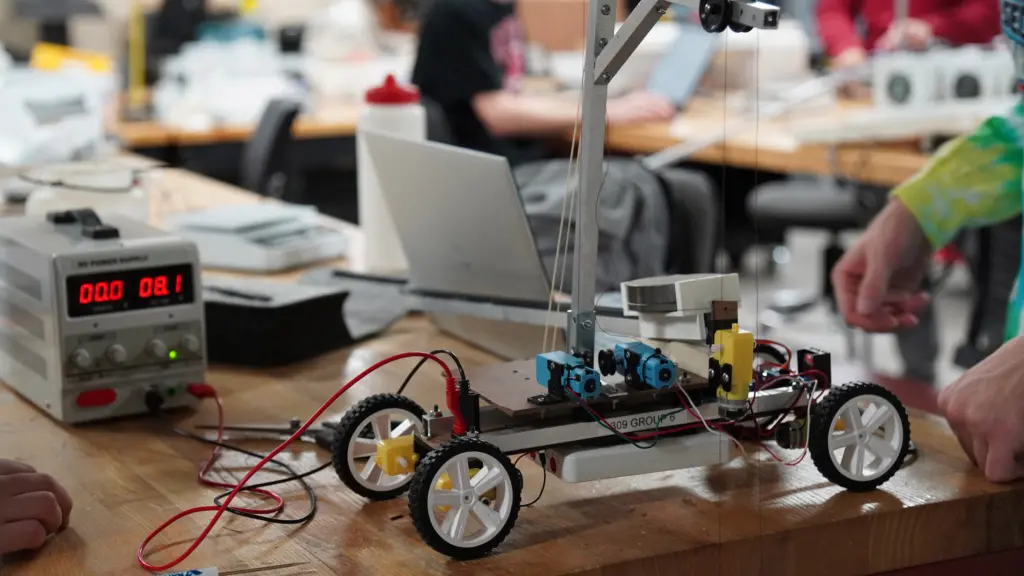

That’s why he wanted to develop a design project that would introduce students to statics concepts through an engaging, hands-on learning experience. In fall 2023, Nellis tasked the students with designing and building small cranes. Their goal: to lift the heaviest mass, as fast as possible, using the smallest crane possible.

“When students build a crane and try to lift something very heavy, the crane tips over—and that’s a statics problem,” Nellis says. “So this problem gives them motivation to learn enough statics to figure out how to keep their cranes from tipping over, and it helps the students see the real applications connected to the math and science they’re learning in their other courses.”

In the first half of the semester, the students learned the basics of key software, mathematical and design tools, such as the 3D solid modeling program SolidWorks, to prepare them for their design project. Each team of students received a kit that contained a microcontroller, a platform, wheels and motors, and the students needed to work together to build the lifting mechanism and construct their crane.

A key aspect of the project is for the students to perform calculations that inform design decisions for their cranes. “Engineers don’t randomly build something and test it,” Nellis says. “They need to first do some calculations based on math and science and then based on these calculations build something and test it and finally interpret the results based on the calculations. A lot of this is new for the students. So this gives them a flavor of what engineers actually do.”

The students had the freedom to explore different approaches to accomplishing their goal, allowing them to gain firsthand experience in assessing the tradeoffs of their designs. For example, some teams decided to try to lift a light mass very quickly, while other teams chose to prioritize lifting the heaviest mass possible.

As part of the course, the students get training in the college’s TEAM Lab and makerspace facilities. They learn fabrication skills so they can feel comfortable using the facilities and start with a strong foundation for tackling hands-on design projects throughout their engineering education.

Student Zoe Gureno embraced the opportunity to learn how to do 3D printing. She ultimately 3D printed more than 30 pulleys and six different hooks to test with her team’s crane. One of her teammates completed a training course for welding and laser cutting, which enabled him to weld the team’s crane arm together and create a custom base plate for the arm and motors.

“I enjoyed that this project involved several hands-on building aspects, such as the arm, the pulleys, the counterweight and the base board, and it offered a lot of opportunities to learn how to use the many tools and resources available at UW-Madison,” Gureno says. “I definitely grew my understanding of 3D printing during this process. I had a lot of fun working on this project, and it was a great introduction to the mechanical engineering department.”

Nellis says ME 201 also aims to foster a sense of community among first-year students in the department, giving them an opportunity to work closely and build friendships with other new ME students. Instead of teaching assistants, the course has undergraduate-level ME student assistants who help run the labs.

“This allows first-year students in the course to interact with ME student assistants who are sophomores, juniors and seniors,” Nellis says. “The older students pass on institutional knowledge and share their experiences, which is incredibly valuable for building community and helping first-year students navigate their major.”

Top photo caption: Students in ME 201 test their crane. All photos by Caitlin Scott.