A new cutting-edge multipoint vibrometer system will enable University of Wisconsin-Madison engineers to more efficiently and accurately measure vibrations in various materials.

UW-Madison is the first university in the United States to acquire the award-winning Polytec MPV-800 multipoint vibrometer. The system’s advanced technical capabilities also open up new research opportunities and applications for UW-Madison scholars.

Laser vibrometers allow engineers to measure vibration without touching the surface being measured, and that’s a key advantage over conventional sensors.

“With a laser vibrometer, a computer controls where the light is pointed and you measure the vibration at that point on the surface,” says Matt Allen, an associate professor of nuclear engineering and engineering physics at UW-Madison. “Although it can only measure one point at a time, a laser vibrometer gives really detailed measurements on a two-dimensional surface.”

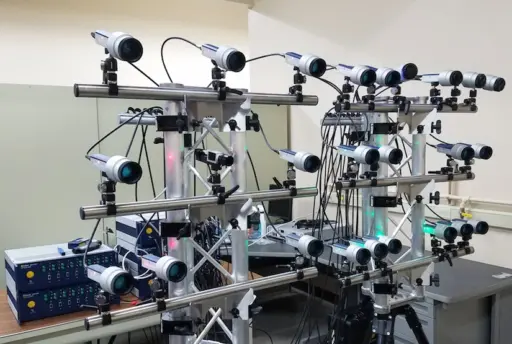

The Polytec MPV-800 multipoint vibrometer. Photo courtesy of Matt Allen.

The Polytec MPV-800 multipoint vibrometer. Photo courtesy of Matt Allen.

The MPV-800 delivers a significant boost in the amount of vibration information researchers can capture. The integrated system uses laser light to take simultaneous vibration measurements at 40 different points on a surface.

The ability to easily take these measurements simultaneously is key, as it allows engineers to fully capture and understand transient events that are difficult to repeat, such as impact between a projectile and the wing of an aircraft. The impact may destroy the structure, so one would only get one chance to take the measurement, says Allen. With this new device, a researcher could take measurements in a test like this at all the relevant locations across the wing at the same time, which isn’t possible with a conventional single-point laser vibrometer, Allen says.

The MPV-800, which features an array of sensor heads, is versatile and can be configured to suit a variety of applications.

Melih Eriten, a mechanical engineering assistant professor at UW-Madison, will use the MPV-800 as his research group’s primary instrument to measure vibrations in various materials, focusing mainly on the transmission of vibrations and waves across interfaces in materials ranging from metals to polymers to biomaterials.

Eriten says the MPV-800 will enable a variety of new research projects and collaborations across UW-Madison. He plans to use the system to assess 3D-printed parts and structures with the goal of detecting any defects that could impede their performance or lead to failure. He will collaborate with mechanical engineering colleagues Tom Turng and Alejandro Roldan-Alzate to conduct this structural health monitoring on 3D-printed fiber-reinforced composites, tissue scaffolds and vascular implants.

Another big advantage of the MPV-800 system, according to Eriten, is that its light wavelength is suited for measuring biomaterials, making it very useful for biomedical applications.

Eriten is also collaborating with Mechanical Engineering Assistant Professor Corinne Henak to learn how cartilage in the human musculoskeletal system works to alleviate the negative effects of shocks and traumatic impacts to the body. They will use the MPV-800 system to measure and characterize the behavior of cartilage and subchondral bone at several locations. They hope to better understand the degree of tissue degradation and damage that leads to common diseases such as post-traumatic osteoarthritis.

In addition, Eriten says the study will uncover mechanisms that drive the superior vibration absorption properties of cartilage—knowledge that could enable the collaborators to develop artificial passive absorbers with unprecedented damping performance. They’ll use the MPV-800 system to test the performance of those soft dampers.

Darryl Thelen, the Bernard A. and Frances M. Weideman Professor of mechanical engineering, also plans to take advantage of the MPV-800’s capabilities for biomedical applications. Thelen and Allen are collaborating to measure vibration waves traveling through tendons. “We use that to measure the tension in the tendon, so we can estimate how much force the tendon feels during walking, running or jumping,” Allen says. “But measuring with just a couple of points gives a very incomplete picture. So we’re hoping this new instrument will give us a lot more information and a better understanding of how the waves propagate through the tendon and what that tells us about the material.”

Allen says the MPV-800 will also be highly valuable for his own research on how nonlinear vibrations affect the thin skin panels on a hypersonic aircraft. At hypersonic speeds, these thin skin panels are subject to very high pressure and will vibrate at large amplitude. In this case, the vibrations are nonlinear and the motion is not repeatable, making it impossible to accurately characterize the event using only a few sample points.

“This instrument should allow us to capture these short nonlinear events, and capture the events completely, so we can understand how to model these panels and structures under high amplitude loads,” Allen says.

The MPV-800 system is already installed, and available to UW-Madison researchers and industry upon coordination with Eriten and Allen.

The MPV-800 won a 2017 R&D 100 Award. The prestigious award program identifies the top-100 technology products of the year. The MPV-800 also received top honors with the coveted R&D Magazine Editor’s Choice Award for attracting the most votes from the expert panel of independent judges.

The MPV-800 was purchased with a grant awarded to Eriten and Allen from the National Science Foundation Major Research Instrumentation Program and supplemental funding from the UW-Madison College of Engineering and the Office of the Vice Chancellor for Research and Graduate Education.