In the fall 2024 semester, a group of freshmen in MS&E 260: Materials Experience—a hands-on introductory course for MS&E majors and the materials science “curious”—designed a final class project to recycle metals from discarded circuit boards. The students, including Peyton Leanna, Krishna Patel and Charles Vlerick, crushed the circuit boards into powder before making a slurry, then precipitated out the metal ions using electrolysis.

To test its results, the team needed to do elemental analysis using a scanning electron microscope (SEM). In previous years, that would have meant reserving time at the room-sized materials science SEM, undergoing specialized training, and paying a fee to use the machine—all of which would have likely halted the freshmen in their tracks. Instead, the group spent a few minutes using a newly purchased tabletop SEM in the MS&E undergraduate laboratory to find that their experiment collected various species of copper, nickel and tin.

It’s not often that first-semester freshmen can operate a scanning electron microscope, without supervision by a teaching assistant or professor. But that’s the type of hands-on experience, and the type of tool, that gets students excited about materials science. Over the last year, MS&E has used the generous donations of alumni to replace aging equipment and purchase new instruments, like the SEM, as part of a campaign to provide a top-notch laboratory experience for every undergraduate who goes through the program.

Over the next few years, the goal is to acquire even more equipment to increase the program’s capacity, train students for emerging fields like semiconductors and polymers, and to prepare for the migration of MS&E’s student learning laboratories to the new 395,000-square-foot Phillip A. Levy Engineering Center, soon to be under construction on the engineering campus.

“Every piece of equipment is touched by every MS&E student during their undergraduate progression,” says Izabela Szlufarska, Harvey D. Spangler Professor and MS&E chair. “The equipment we purchase impacts every single student in the department.”

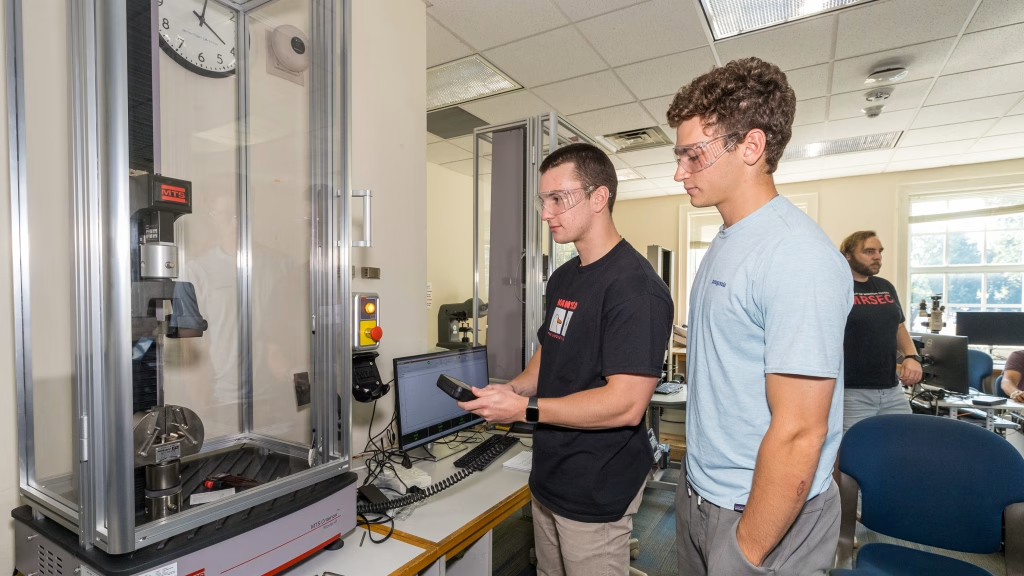

Besides two tabletop scanning electron microscopes, the department has also used alumni gifts to purchase two new tensile testers, an atomic force microscope, a thermogravimetric analyzer and differential scanning calorimeter for polymer study, and an xray diffractometer. It has also invested in a new photolithography system and metals thin film evaporator, both important in fabricating semiconductors.

“These recent major purchases have transformed our lab experience into something very modern and exciting,” says Beckwith-Bascom Professor Michael Arnold, associate chair of undergraduate studies for MS&E. “There are a lot of semiconductor companies that have been visiting campus, like TSMC and others. They’re desperate to hire materials scientists for their plants, so we’re trying to better train our students in semiconductor processing. This equipment helps use move in that direction.”

Students in MS&E 362: Synthesis and Characterization Lab. Photos: Joel Hallberg

Students in MS&E 362: Synthesis and Characterization Lab. Photos: Joel Hallberg

Phase one of these upgrades has expanded the department’s capacity to graduate 50 undergraduate students per year. Phase two will require even more instruments and equipment to expand that capacity to more than 100 graduates per year. The advanced instruments will also greatly improve the capabilities of student groups in their required capstone senior design course, which provides them with real-world project management experience.

The new instruments will also be at the heart of two new custom labs on the second floor of the Phillip A. Levy Engineering Center dedicated to MS&E undergraduate laboratory courses. One will include banks of optical microscopes as well as the new scanning electron microscopes, atomic force microscope, xray diffractometers, thermal analysis tools and plenty of bench space for custom student projects. There will also be a separate dark room to house a suite of semiconductor-related tools, including the photolithography system, cutting and polishing equipment, spin coaters, and other deposition instruments. “It will be like a quasi-clean room,” says Arnold. “Students can learn how to use all the tools without having to go into a clean room, which has limits on how many students it can handle and also has a per-hour cost.”

A second wet lab will include eight fume hoods: safety devices that protect users from hazardous vapors and particles during experiments. This will help the department deepen its focus on soft materials. “It will be really transformational and allow us to offer more on the soft materials side of things, like polymers, that you synthesize in a beaker,” says Arnold. “Polymers are a really important part of materials science, and this will allow us to properly educate our students in this area.”

The department hopes that, with continued support, it will be able to fulfill this vision and develop the facilities needed to offer a state-of-the-art, flexible materials science education.

“Laboratory education is an essential part of our undergraduate curriculum. These courses provide students with hands-on experiences and an understanding they can’t get from lecture courses alone,” says Szlufarska. “They help connect theory to real-world problems, and students learn how to apply techniques and use machines that employers value.”

In MS&E, every student will touch every piece of lab equipment—meaning your contribution positively impacts each and every student within the department. To learn more about the department’s needs and to contribute to its laboratory campaign, contact Director of Development Andrew Snyderman at andrew.snyderman@supportuw.org or (608) 572-1588.