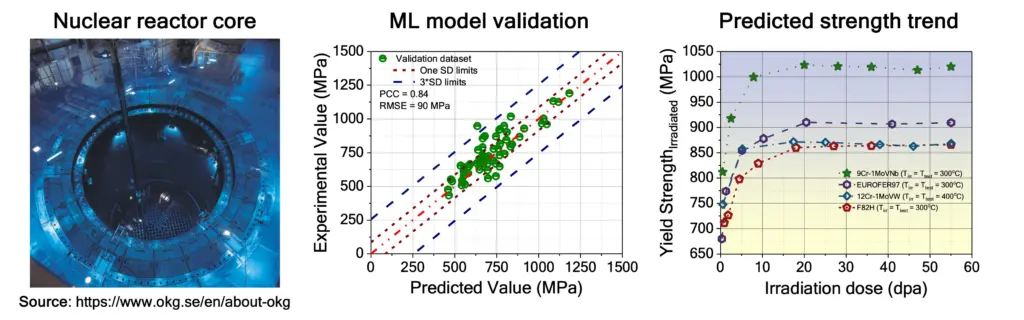

A team of researchers from the University of Wisconsin-Madison and Indian Institute of Science (IISc) has developed machine learning models that can predict changes in the mechanical behavior of materials in a nuclear reactor after they have been irradiated with neutrons.

The researchers demonstrated that these predictive models can significantly reduce the time and cost associated with conducting experiments on neutron irradiation of materials and accelerate the development of materials for advanced nuclear reactors. The team published a paper detailing its advance in October 2023 in the journal Fusion Engineering and Design.

In this project, the researchers focused on special type of steel called ferritic/martensitic steel because it’s more resistant to damage caused by nuclear radiation. A variety of ferritic/martensitic steels can be made by changing the composition and processing conditions, and they behave differently under different levels of radiation exposures at different temperatures. Therefore, it’s important to thoroughly investigate the effects of neutron irradiation on ferritic/martensitic steels to identify the most suitable option for a specific irradiation level in a given reactor.

However, future developments in ferritic/martensitic steels for advanced reactors will require neutron irradiation data, which can be challenging to obtain experimentally because of scarcity of nuclear testing facilities, and the large expenses and time commitments involved.

“Machine learning is extremely valuable for this application because doing neutron irradiation experiments in a test reactor and post-irradiation testing and characterization of the steels can cost millions of dollars and take about six or seven years, not to mention there are very few test reactors in the world,” says Kumar Sridharan, Grainger Professor in the Department of Nuclear Engineering and Engineering Physics and the Department of Materials Science and Engineering at UW-Madison, an author on the recent journal paper. “So I think this is an excellent application of machine learning with a lot of practical value.”

Image courtesy of Indian Institute of Science

Image courtesy of Indian Institute of Science

One approach to investigating the effects of neutron irradiation on these steels is to use physics-based models. However, they require extensive defect characterization data as input, which is missing in most experiments reported in literature.

So, the researchers developed an alternative approach that harnesses machine learning models. They used a large body of data from previous neutron irradiation experiments and applied machine learning concepts to predict changes in mechanical properties for future ferritic/martensitic steels.

The team used an algorithm called SHAP to pinpoint the most important input parameters/variables influencing the strength of ferritic/martensitic steels upon irradiation. Using these variables, the researchers deployed four machine learning algorithms to predict the strength of different ferritic/martensitic steels subjected to varied radiation levels and temperatures.

“This collaboration between IISc and UW-Madison highlights the efficacy of sophisticated yet straightforward machine learning techniques in accurately forecasting the performance of materials such as neutron-irradiated ferritic/martensitic steels,” says Assistant Professor Ankur Chauhan, of Indian Institute of Science. “This marks a substantial advancement in securing dependable structural materials for the next-gen nuclear reactors.”

Additional authors on the journal paper from Indian Institute of Science include Nichenametla Sai Jai, and Punit Rathore.

A version of this story was originally published by Indian Institute of Science.