These days, we increasingly rely on our cell phone cameras to capture virtually every aspect of our lives. Far too often, however, we end up with photos that are a sub-par reproduction of reality.

And while operator error sometimes comes into play, most likely, the camera’s digital image sensor is the real culprit. A flat silicon surface, it just can’t process images captured by a curved camera lens as well as the similarly curved image sensors—otherwise known as the retinas—in human eyes.

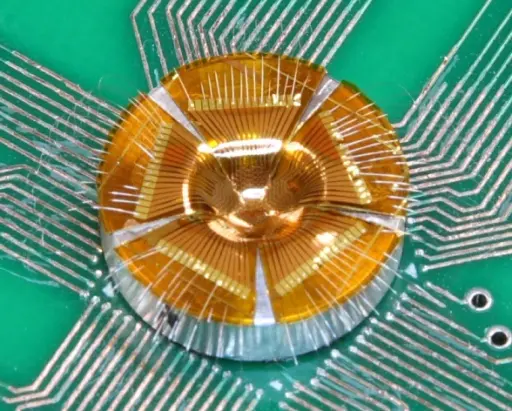

A concave version of the digital image sensor bends inward for creating a hemispherical focal plane array. Courtesy of Yei Hwan Jung and Kan Zhang.

A concave version of the digital image sensor bends inward for creating a hemispherical focal plane array. Courtesy of Yei Hwan Jung and Kan Zhang.

In a breakthrough that could, for example, lead to cameras with beyond-the-state-of-the-art features such as infinite depth of field, wider view angle, low aberrations, and vastly increased pixel density, flexible optoelectronics pioneer Zhenqiang (Jack) Ma has devised a method for making curved digital image sensors in shapes that mimic an insect’s compound eye (convex) and a mammal’s “pin-hole” eye (concave).

The Lynn H. Matthias and Vilas Distinguished Achievement Professor of electrical and computer engineering at the University of Wisconsin-Madison, Ma, his students and collaborators described the technique in the Nov. 24, 2017, issue of the journal Nature Communications.

Curved image sensors do exist. Yet even though they outperform their flat counterparts, they haven’t made it into the mainstream—in part, because of the challenges inherent in a manufacturing method that involves pressing a flat, rigid piece of silicon into a hemispherical shape without wrinkling it, breaking it or otherwise degrading its quality.

Ma’s technique was inspired by traditional Japanese origami, or the art of paper-folding.

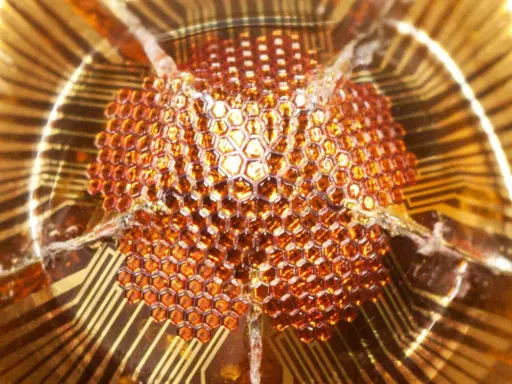

A convex version of the digital image sensor bends like a soccer ball for mimicking an insect’s compound eye. Courtesy of Yei Hwan Jung and Kan Zhang.

A convex version of the digital image sensor bends like a soccer ball for mimicking an insect’s compound eye. Courtesy of Yei Hwan Jung and Kan Zhang.

To create the curved photodetector, he and his students formed pixels by mapping repeating geometric shapes—somewhat like a soccer ball—onto a thin, flat flexible sheet of silicon called a nanomembrane, which sits on a flexible substrate. Then, they used a laser to cut away some of those pixels so that the remaining silicon formed perfect seams, with no gaps, when they placed it atop a dome shape (for a the convex detector) or into a bowl shape (for a concave detector).

“We can first divide it into a hexagon and pentagon structure—and each of those can be further divided,” says Ma. “You can forever divide them, in theory, so that means the pixels can be really, really dense, and there are no empty areas. This is really scalable, and we can bend it into whatever shape we want.”

That pixel density is a boon for photographers, as a camera’s ability to take high-resolution photos is determined, in megapixels, by the amount of information its sensor can capture.

Currently, the researchers’ prototype is approximately 7 millimeters, or roughly a quarter-inch, in diameter. That’s still a bit bulky for your cell phone, but Ma says he can make the sensor even smaller. “This membrane is a very big advance in imaging,” he says.

Other authors on the paper include Kan Zhang, Yei Hwan Jung, Solomon Mikael, Jung-Hun Seo, Munho Kim, Hongyi Mi, Han Zhou, Zhenyang Xia, Weidong Zhou and Shaoqin Gong. They have patented the advance through the Wisconsin Alumni Research Foundation

This work was supported by the Air Force Office of Scientific Research (AFOSR): Presidential Early Career Award in Science & Engineering (PECASE), Grant FA9550-09-1-0482.