As a high school student in the San Francisco Bay Area during COVID pandemic lockdowns, Ben Levy had a lot of free time on his hands while being stuck at home. To combat his boredom, he decided to try to build a humanoid robot in his family’s garage.

“I had an Arduino kit, which has simple microcontrollers, and a bit of experience using it at a summer camp,” Levy says. “I thought it would be a fun challenge to see what I could build.”

Ultimately, he created a rudimentary gesture device that resembles a robotic hand. His setup involved wearing sensors on one of his hands, allowing the robot hand to mimic his gestures.

Later, as a mechanical engineering freshman at the University of Wisconsin-Madison, he took ME 201: Introduction to Mechanical Engineering, and stopped by Assistant Professor Michael Wehner’s office hours to discuss an idea related to the course’s hands-on design project. The conversation eventually moved on to Wehner’s research, which is focused on robotics, machine interaction and soft systems.

“With my growing interest in robotics, I found Professor Wehner’s research really exciting,” Levy says. “I showed him a video demo of the humanoid robot I built in high school, and he offered me an opportunity to work in his research lab.”

With Wehner’s mentoring, Levy wanted to build a haptic glove for virtual reality that not only could be used as a controller in a video game, but also allow users to “feel” virtual objects as they played.

Levy teamed up with mechanical engineering graduate student Megh Doshi, a member of Mechanical Engineering Associate Professor Michael Zinn’s research group, for the project. For their prototype, they focused on developing a “layer jammer” device to serve as the actuator for haptic feedback in the glove. To make it, they stacked sheets of paper and put them inside a plastic bag. Applying a vacuum to the sealed bag compresses the paper and makes it stiff. Removing the vacuum returns the device to its original soft, flexible state.

Levy says the simplicity of their layer jammer makes it far cheaper and more user friendly than the very expensive actuators used in commercial virtual reality gloves, which use complicated designs and control methods.

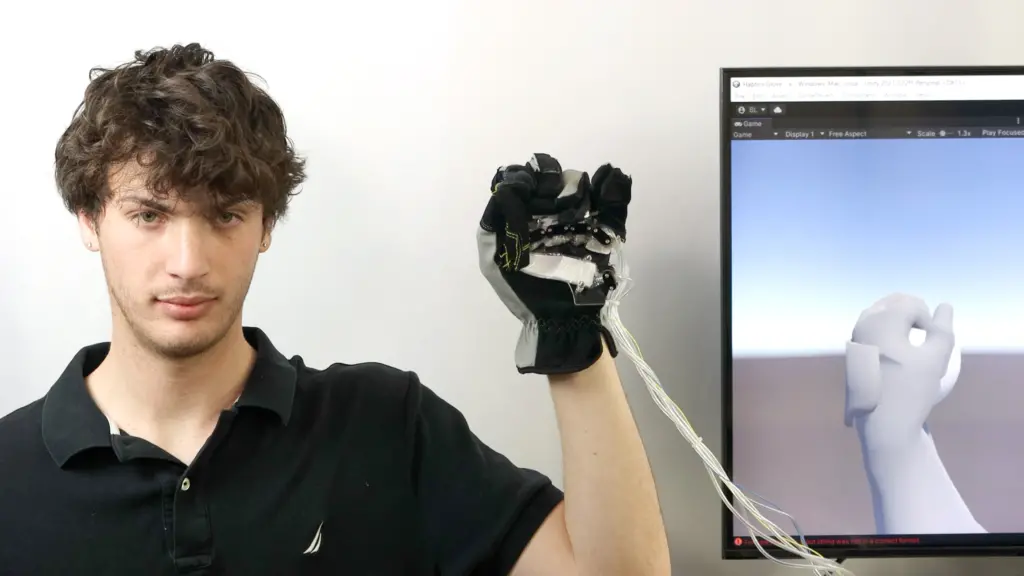

The students’ haptic glove allows users to feel virtual objects in a video game environment. The glove uses layer jammers made of sheets of paper to provide haptic feedback. Photo: Joel Hallberg.

The students’ haptic glove allows users to feel virtual objects in a video game environment. The glove uses layer jammers made of sheets of paper to provide haptic feedback. Photo: Joel Hallberg.

“The layer jammer offers a very cheap way to transition between high transparency, where it feels like nothing is stopping your finger, to high impedance, where it feels like you’re touching something hard,” Levy says.

To start, Levy and Doshi had to figure out a way to consistently manufacture the layer jammers so they’d operate reliably. Levy says this was a surprisingly complex challenge, which involved trying to find ways to maintain the highest level of vacuum.

Next, they performed thorough characterization of the devices, evaluating key parameters so they could be designed into many different wearables. As a freshman new to engineering, Levy says this characterization work had a big learning curve. “Getting reliable data from testing the devices was a huge challenge and the most difficult engineering problem I faced with this project,” he says.

Levy and Doshi persevered, and once they managed to get reliable data, they focused on building the glove based on the key parameters they identified. Levy took the lead on building the glove, with the goal of integrating the layer jammers so that they would conform well to the hand. To achieve this, he designed a base plate and mounted the jammers on it. Making the glove required some sewing skills as well.

Undergraduate student Ben Levy demonstrates how the glove can control a virtual hand and the user can feel and see a virtual ball in a live video game environment. Image courtesy of Michael Wehner.

Undergraduate student Ben Levy demonstrates how the glove can control a virtual hand and the user can feel and see a virtual ball in a live video game environment. Image courtesy of Michael Wehner.

“I called my mom to ask her for some sewing tips and also watched some sewing tutorials online,” Levy says. “Building the glove was a blast, and this was the part of the project that I enjoyed the most.”

Lastly, Levy created a video game environment using Unity software. Wearing the glove, he could control a virtual hand in the game and actually feel and see a virtual ball in a live video game environment.

The duo submitted their work to the IEEE Haptics Symposium 2024, which accepted their paper. Doshi presented the research at the conference.

“Having a paper accepted to a conference is a great accomplishment for any undergraduate, but it was particularly inspiring for a freshman,” Wehner says. “Ben is a very talented student and I’m impressed by his work.”

Levy, who is now a sophomore, says this hands-on research project was a wonderful learning experience that helped deepen his understanding of concepts in his engineering courses. For example, he entered his mechanics of materials course with an already strong understanding of beam deformation due to his work on this project.

“I’m very grateful to Professor Wehner for giving me the opportunity and the flexibility to pursue this project and help guide the creative direction. He has been fantastic to work with,” Levy says. “This experience has definitely confirmed that engineering is what I want to do.”

Featured image caption: Mechanical engineering sophomore Ben Levy makes an adjustment to his haptic glove. Credit: Joel Hallberg.

Layer Jammers in a Simulated Environment Soft Haptic (S.E.S.H.) Glove

Layer jammer demo with weight

Layer jammer in curved position demo