For clean energy sources like solar or nuclear, molten salt is somewhat of a wonder material. In concentrated solar power plants, for example, the sun’s heat can be stored in the liquid for long periods of time. Conversely, next-generation nuclear reactors can use molten salt as a coolant and as a solvent for uranium fuel—making the reactors potentially smaller, safer, less complex and more economical than current nuclear power plants.

However, molten salt is well-known to corrode metal, so researchers are working hard to create metal alloys that can withstand constant wearing away, specifically when they’re exposed at high temperatures. But progress has been slow going—and that, says Adrien Couet, also has kept molten salt technologies from reaching their potential in the energy industry, too.

“Developing those new materials is an extremely lengthy and costly process, which is why industry is lacking alloy options for developing molten salt technologies,” says Couet, an associate professor of engineering physics at the University of Wisconsin-Madison.

That’s about to change. Couet and his collaborators have developed an innovative and fast approach that brings together additive manufacturing, high-temperature corrosion testing, modeling, and machine learning to dramatically speed up the process of developing new metal alloys.

The researchers detailed their findings in a paper published May 7, 2022, in the journal Advanced Science.

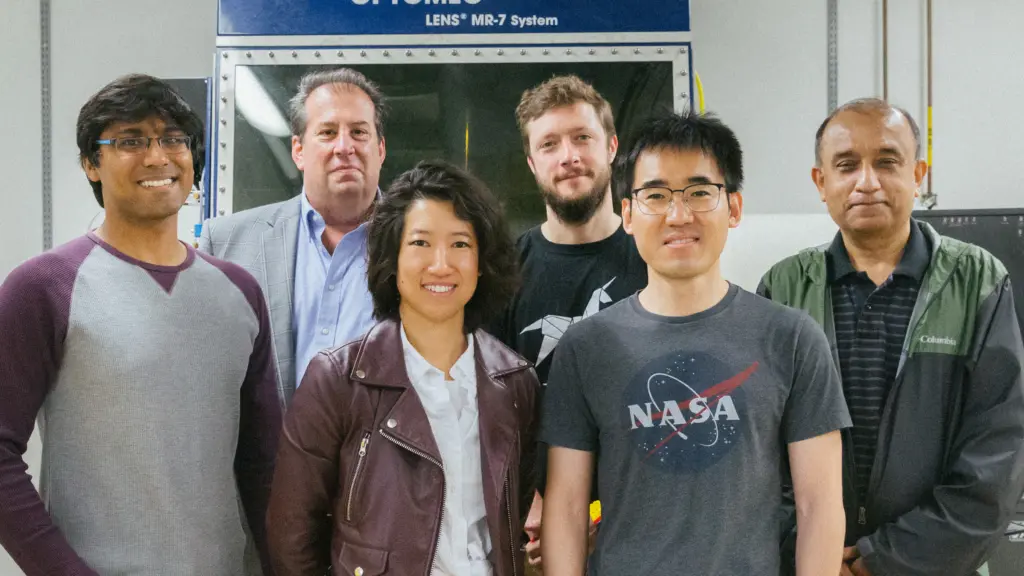

UW-Madison researchers developed an innovative approach to dramatically speed up the process of developing new metal alloys. From left: Phalgun Nelaturu, Dan Thoma, Bonita Goh, Adrien Couet, Yafei Wang, and Kumar Sridharan.

UW-Madison researchers developed an innovative approach to dramatically speed up the process of developing new metal alloys. From left: Phalgun Nelaturu, Dan Thoma, Bonita Goh, Adrien Couet, Yafei Wang, and Kumar Sridharan.

“Traditionally, a researcher could maybe investigate a handful of alloys over a few years,” Couet says. “Now, with this new approach, we can study about 100 to 150 alloys in six months to a year, so it’s a big acceleration of the process.”

The new approach goes like this: First, the researchers use 3D printing to produce small metal blocks that roughly resemble Legos. Each one of the knobs on these 3D-printed blocks is made of a different alloy.

“This is a relatively new use of 3D printing, and it allows us to create many different types of metal alloys far more quickly than with conventional methods,” says Yafei Wang, a scientist in Couet’s research group and first author on the paper.

Next, the researchers deposit small molten salt droplets on the surface of each alloy and study how the materials hold up at high temperatures. These corrosion tests produce huge amounts of data, which the researchers analyze using machine learning methods. Couet says machine learning is allowing the team to zero in on materials that are especially promising.

In addition, the team discovered a new mechanism that affects alloys in molten salt corrosion. “This finding was unexpected, and it shows how our approach can also help drive new discoveries,” says Couet.

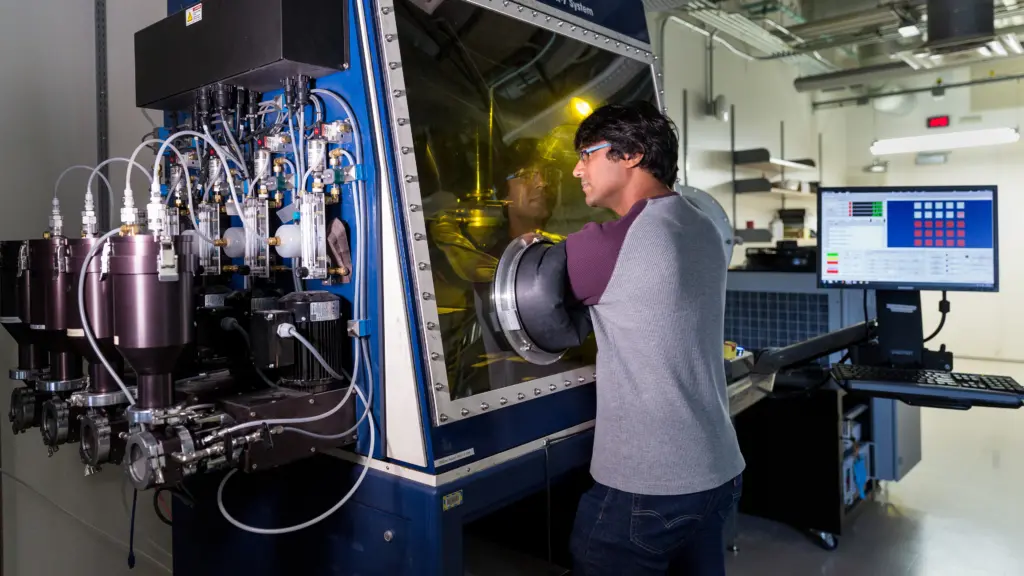

Assistant Scientist Phalgun Nelaturu conducts research on metal alloys for molten salt applications.

Assistant Scientist Phalgun Nelaturu conducts research on metal alloys for molten salt applications.

This work was supported by funding from U.S. Department of Energy’s Advanced Projects Research Agency-Energy (ARPA-E).

Additional UW-Madison co-authors on the paper include: Bonita Goh, Phalgun Nelaturu, Najlaa Hassan, Raphaelle David, Michael Moorehead, Materials Science and Engineering Professor Dan Thoma and Kumar Sridharan, a professor of engineering physics and materials science and engineering; Thien Duong and Santanu Chaudhuri from Argonne National Laboratory; and Adam Creuziger and Jason Hattrick-Simpers from the National Institute of Standard and Technology.