Engineers play a critical role in solving challenges, whether they’re devising technology for the smart farms of the future, building fusion reactors to drive new sustainable energy possibilities, or creating new materials for safer protective helmets.

And when University of Wisconsin-Madison engineers solve challenges, they frequently do so on behalf of—or in partnership with—communities and companies across the state of Wisconsin.

Faculty, staff and student researchers pursue work that benefits whole industries. Instructors and students collaborate directly with municipalities big and small to improve life at the local level. And every day, our 16,000-plus engineering alumni who call Wisconsin home go to work in communities in each of the state’s 72 counties.

Here are just a handful of examples of ways in which Badger Engineers benefit our state.

Relevant research

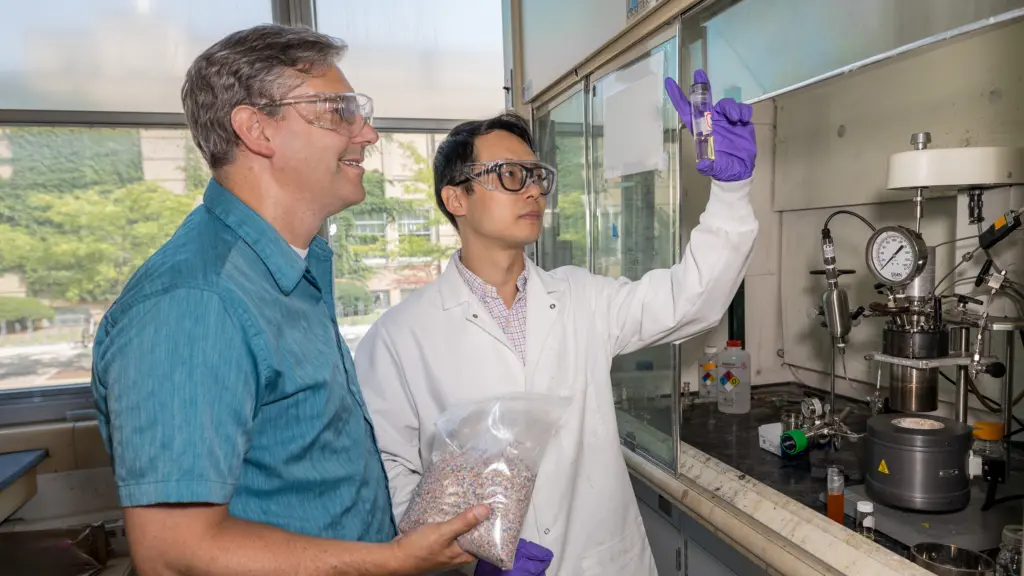

Using a process called hydroformylation, Professor George Huber (left) and postdoctoral researcher Houqian Li are able to recover the olefins in an oil made from waste plastic and transform them into high-value chemicals. Photo by: Joel Hallberg.

Using a process called hydroformylation, Professor George Huber (left) and postdoctoral researcher Houqian Li are able to recover the olefins in an oil made from waste plastic and transform them into high-value chemicals. Photo by: Joel Hallberg.

Chemical and biological engineering faculty and graduate students are leading an effort to convert non-food crops into renewable energy sources and valuable renewable chemicals. Aiming to reduce phosphorous in Wisconsin’s waterways and make better use of one of the state’s other abundant resources, CBE researchers also are developing a system to collect cow manure and transform it into a balanced biofertilizer.

Elsewhere on tomorrow’s smart farm, an electrical and computer engineering professor and her students are designing and deploying low-power wireless sensors that can, for example, remotely monitor and relay information about the “health” of an entire field.

Chemical and biological engineering faculty and students have caught the eye of many of the state’s plastic packaging manufacturers with pioneering technology that allows them to recycle “junk” plastic waste into high-value chemicals.

With industry partners, including Milwaukee Tool and Trek Bicycle of Waterloo, our mechanical engineers are leading a major transdisciplinary effort to develop better technologies for detecting and preventing concussions and other traumatic brain injuries. A team led by industrial engineering researchers, meanwhile, is working with Mercury Marine at the company’s Fond du Lac, Wisconsin, plant to study the use of collaborative robots in manufacturing lines.

UW-Madison’s engineering research facilities are also a boon to local companies. Staff at Beloit-based NorthStar Medical Radioisotopes, which makes medical radioisotopes and radiopharmaceuticals, is leveraging the UW Nuclear Reactor’s capabilities to help bring those products into the healthcare market more quickly.

Smart students

From left: Biomedical engineering undergraduate students Josh Andreatta, Annabel Frake, Tim Tran, Samuel Skirpan and Roxi Reuter demonstrate their design project. Photo by: Tom Ziemer.

From left: Biomedical engineering undergraduate students Josh Andreatta, Annabel Frake, Tim Tran, Samuel Skirpan and Roxi Reuter demonstrate their design project. Photo by: Tom Ziemer.

Working with Noah, an autistic Madison resident, and his mother, a group of biomedical engineering undergraduates designed and built a custom tandem attachment for an electric bike so that Noah can continue to safely and securely experience bicycling and explore his community. Another group of BME undergrads collaborated with Cottage Grove fitness manufacturer Johnson Health Tech to design an adaptive rowing machine for people who use wheelchairs.

Four materials science and engineering seniors partnered with a fast-growing Wisconsin-based additive manufacturing company that creates filaments for 3D-printing metal components; the students set up sophisticated experimental procedures for testing parts printed using the company’s products, then presented the company detailed physical materials data on the products.

Through the UniverCity Year program on campus, several civil and environmental engineering undergraduates have assessed community challenges in Adams County (space and systems issues in its health and human services building) and Marathon County (efficient goal-oriented space use in two county-own buildings).

And a native of Boyd, Wisconsin, used her PhD program in civil and environmental engineering to study radium in Wisconsin’s ground and well water, particularly in the Fond du Lac area; she’s now working full time with the Wisconsin Geological and Natural History Survey as a groundwater resources scientist.

Startup incubator

Katy Jinkins (PhDMS&E ’20) is the co-founder and CEO of SixLine Semiconductor, a spinoff company from the lab of Professor Michael Arnold. Submitted photo.

Katy Jinkins (PhDMS&E ’20) is the co-founder and CEO of SixLine Semiconductor, a spinoff company from the lab of Professor Michael Arnold. Submitted photo.

A host of Wisconsin startup companies founded by or based on innovations developed in our research labs are contributing not only to the state’s economic growth, but they’re also solving important challenges. For example, Stem Pharm’s “brain in a dish” allows researchers to study diseases and screen new drugs ahead of animal or human trials, while C-Motive is developing an innovative electric motor that operates much more efficiently than traditional motors. Flambeau Diagnostics offers mobile diagnostic testing to reach underserved communities.

Flux XII is working toward commercial-scale aqueous organic redox flow batteries that could store energy from renewable sources like wind and solar. Realta Fusion and Type One Energy Group, two new companies seeking to further develop promising fusion energy technologies, recently have brought millions of dollars in seed and research and development funding to Wisconsin. SHINE Technologies, founded by an alumnus, is also pursuing fusion energy while producing critical medical isotopes used for cancer therapies and diagnostic imaging.

Clandestine Materials Detection uses a nuclear detection system to uncover land mines and other explosives.

Earth Repair, a company that seeks to pair carbon capture with industrial waste upcycling, grew out of student competition. Pyran harnesses agricultural waste to produce useful chemicals.

SixLine Semiconductor, co-founded by a materials science and engineering alumna, is developing materials for advanced electronics based on aligned carbon nanotubes, while Atrility Medical, a company that spun out of an undergraduate biomedical engineering project, is among nine companies to grow out of BME design over the past decade and a half. With its product, Atrility is filling a critical postoperative care need for newborns with heart defects.

Top photo: Anna Konstant, a PhD student in Robert Radwin’s lab, examines a collaborative robot that could be used in aviation manufacturing. Photo: Joel Hallberg.